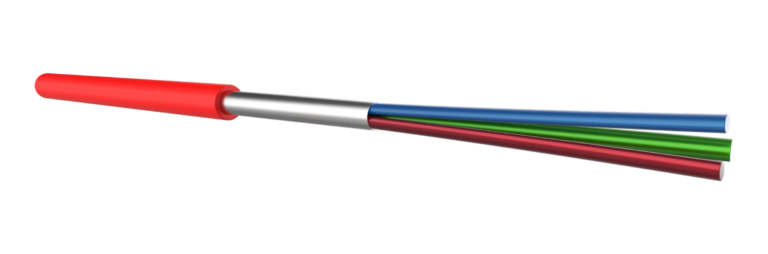

FIBER IN METAL TUBES

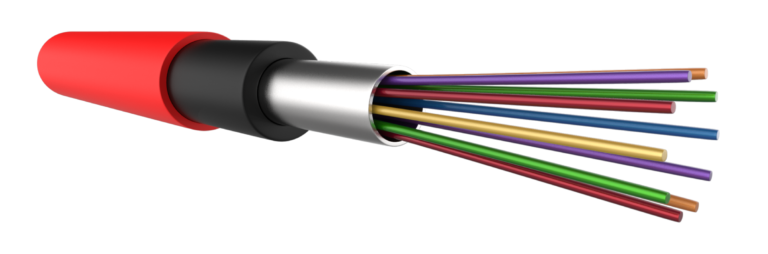

Harsh Environment Cable (1/4")

- Built for the toughest conditions, including the Oil & Gas Industry

- Performs in high pressure / high temperature (HPHT)

- Distributed Temperature Sensing (DTS) and Distributed Acoustic Sensing (DAS)

Fiber Optic Sensing in Harsh Environments

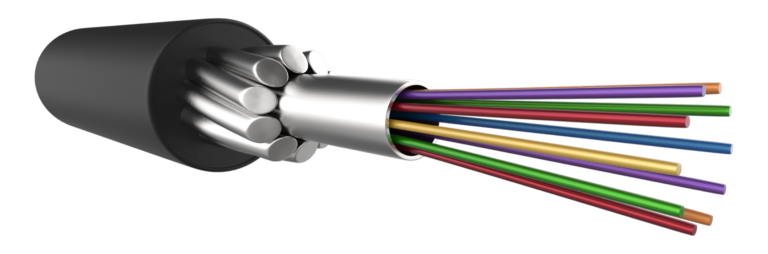

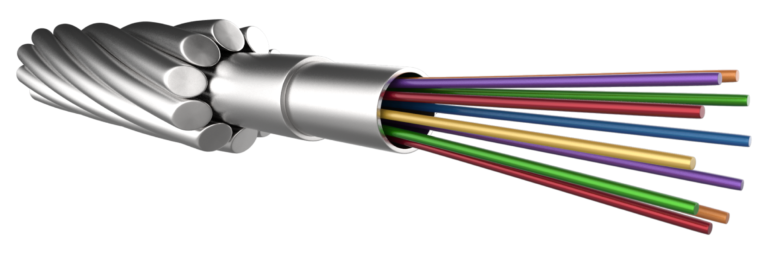

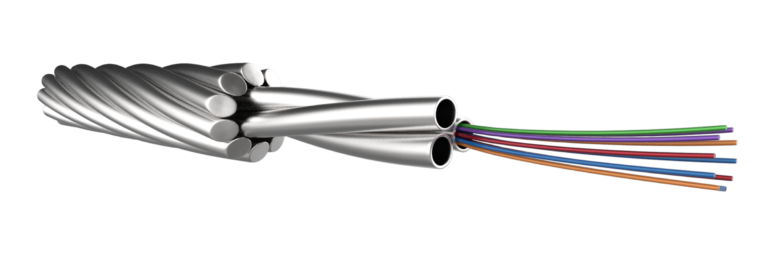

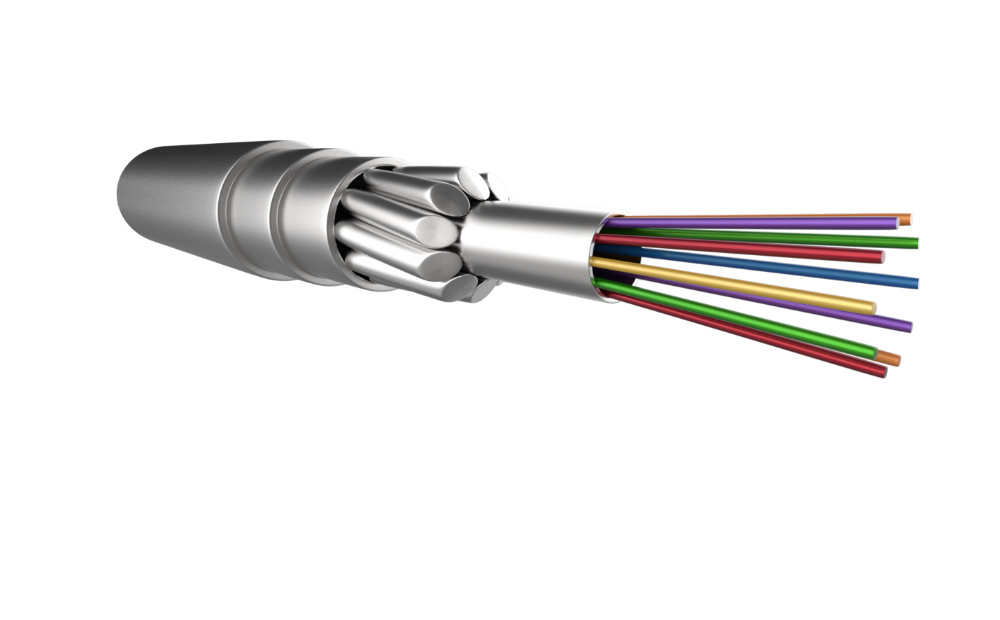

Our Harsh Environment Cable (HEC) performs in the most demanding conditions imaginable. The configuration ensures maximum crush resistance and tensile strength. Moreover, it functions at extreme temperatures, ranging from -60°C to +300°C (-76°F to +572°F), and it’s a popular fiber optic sensing cable for the Oil & Gas Industry, among other harsh surroundings.

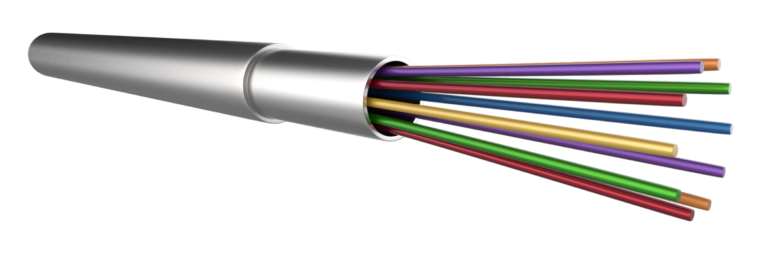

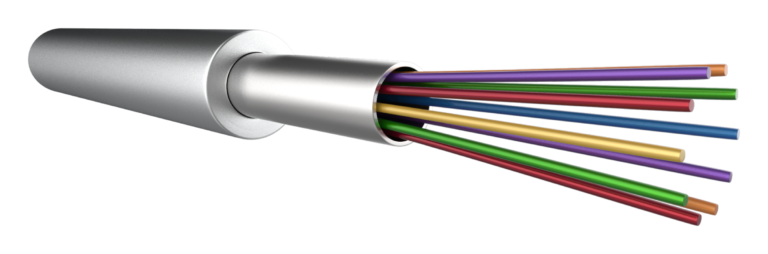

The production process includes a hermetical seal on the inner layers, contributing an additional dimension of protection against corrosive agents. In addition, as many as 24 optical fibers can fit into a single cable, making the heavily protected cable solution ideal for fiber optic sensing and data transmission in the most challenging environments.

The Harsh Environment Cable is capable of Distributed Temperature Sensing (DTS) and Distributed Acoustic Sensing (DAS) in high pressure/high temperature (HPHT) settings. If this sounds like what you need from a fiber optic cable, get in touch and talk to one of our experts today. We always listen to your unique challenge and deliver a custom solution that’s perfect for you.

-

up to 144 fibers

-

extreme crush resistance

-

Harsh environment

Specifications

| Product abbreviation | HEC |

| Cable usage | Data Transm. & Sensing |

| Total outer diameter | 6.35 mm (1/4”) |

| Approx. Cable weight | 200 kg per km |

| Maximum fiber count | 24 (250µm) |

| Operational temperature range | -60°C up to +800°C |

| Maximum continuous length | Up to 20 km |

| Ultra-High tensile strength | > 20 kN |

| Ultra-High crush resistance | Tests acc. latest standards |

| Cost effective steel grade mixing | Wide range possible |

| High corrosive resistance | Made of Alloy material |

| Perfect usage for | Heavy industry applic. |

All values, product specifications and other given data are subject to change without notice to improve reliability, function, design or otherwise. Information contained in this data sheet are up-to-date as at the date of issue. As NBG cannot control or anticipate the conditions under which this product may be used, each user should review the information in specific context of the planned use. To the maximum extent permitted by law, NBG will not be responsible for damages of any nature resulting from the use or reliance upon the information contained in this data sheet.

Product overview created by Patrick Weissinger – 21.03.2019

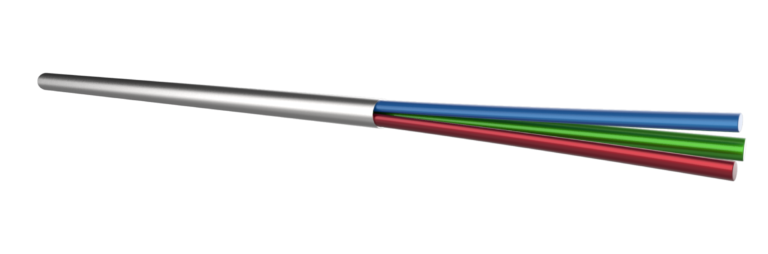

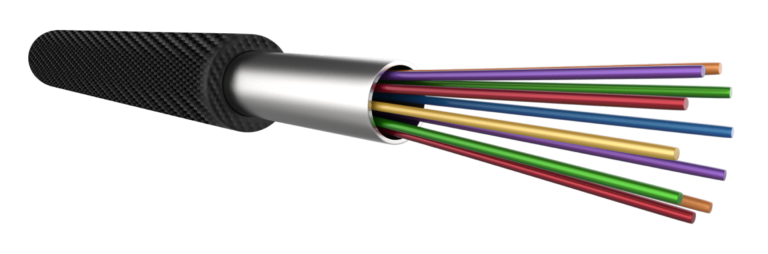

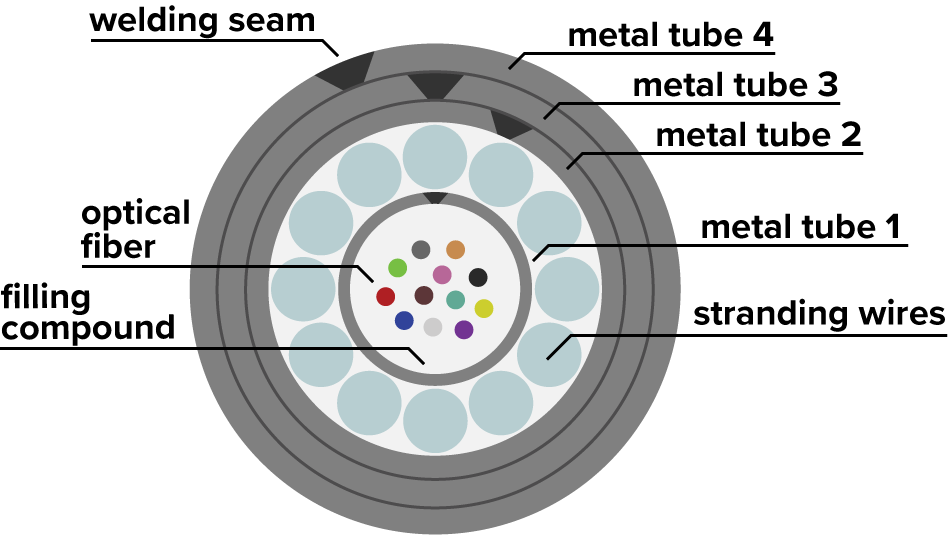

Optical fibers

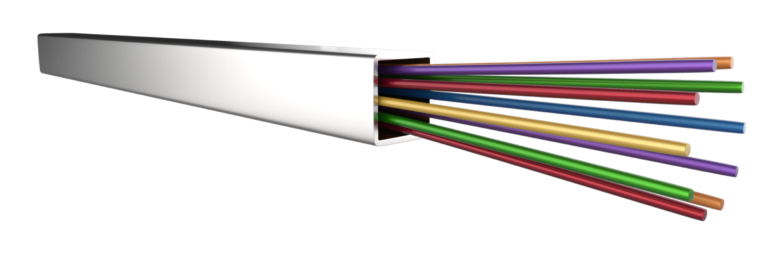

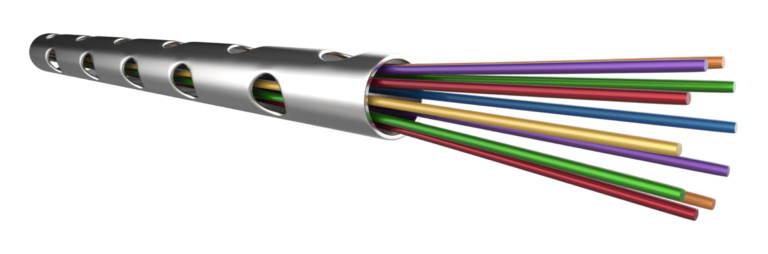

Metal tube 1

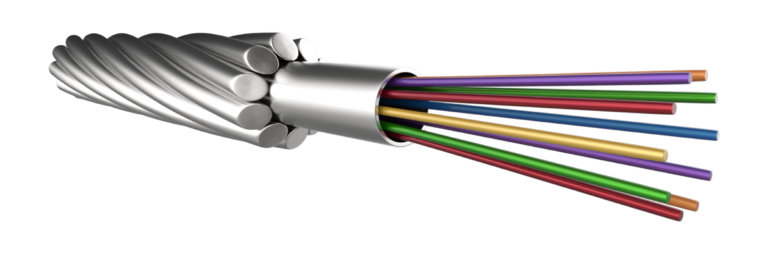

Stranding wires

Metal tubes 2-4

Applications