OIL & GAS

Specialty cables For oil & gas

Optimized FIMT designs made for harsh environments.

Maximize well production yields and monitor critical infrastructure.

- Home

- Oil & Gas

How we help your production

Fiber optics for oil and gas serve as links for data, control and for sensing of various attributes. Since fiber optics offer large bandwidth in a compact cable, size, weight and installation time are reduced. With sensor applications, fiber optic solutions provide a wide range of data about environmental conditions such as temperature, oil reserve levels and equipment performance or status.

Reduction of maintenance

expenses

Reduction of forced downtime

of technical facilities

Reduction of emergency reaction time

Optimization of equipment

operation

Download our FREE guide on how to lower your overhead through use of Fiber Optic Sensing today!

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

We have solutions for every part of the process

- Refineries

- Temperature monitoring

- Health monitoring based on DAS

- Pipeline

- Leakage detection

- Temperature monitoring

- Flow measurement

- Refineries

- Temperature monitoring

- Health monitoring based on DAS

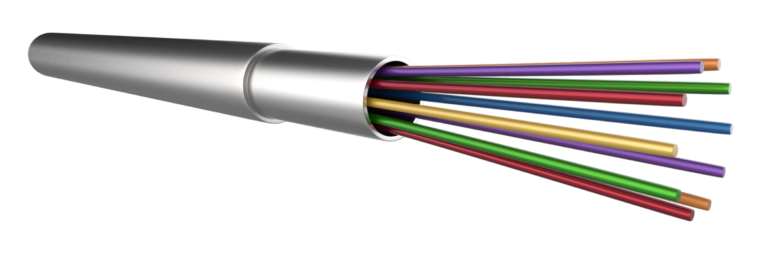

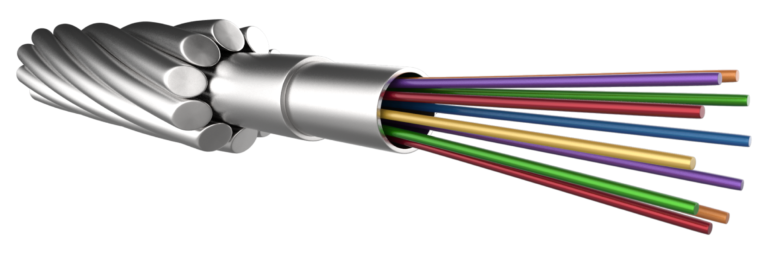

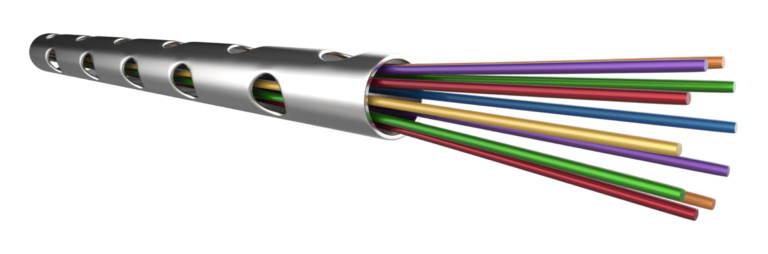

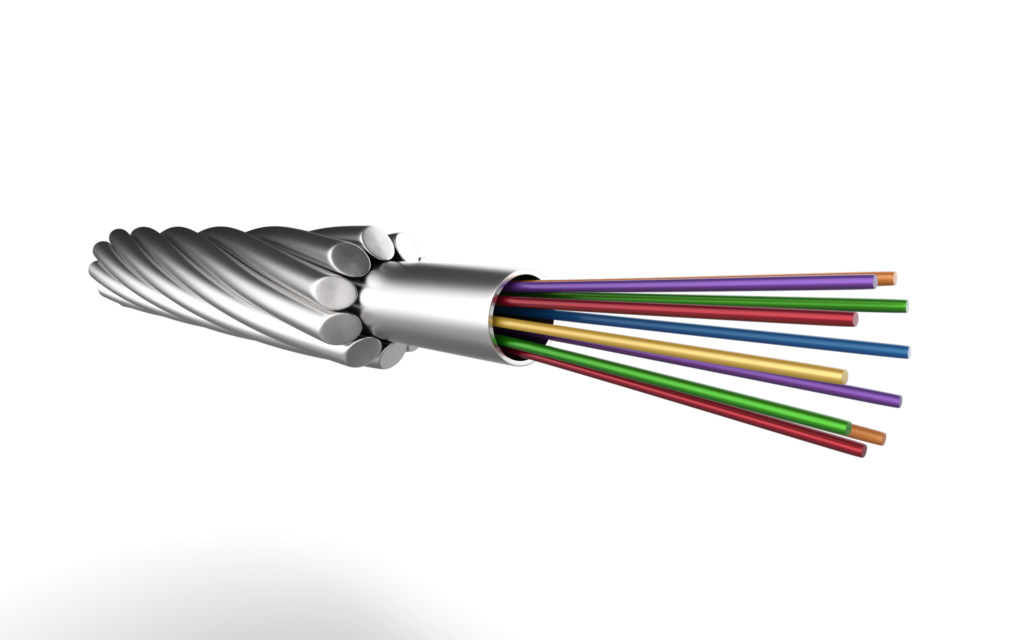

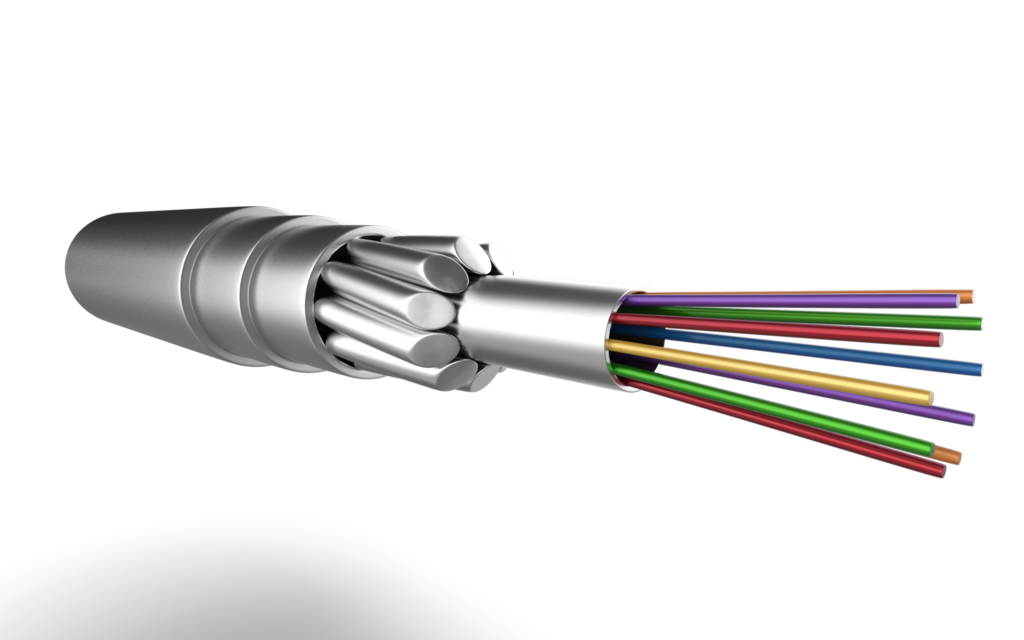

Stranded single layer

- Tensile & crush optimized

- Flexible construction

- Up to 18 wires

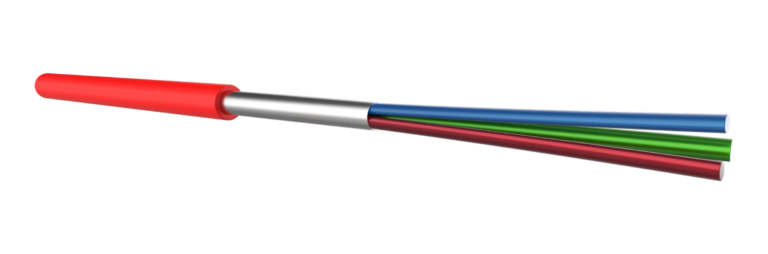

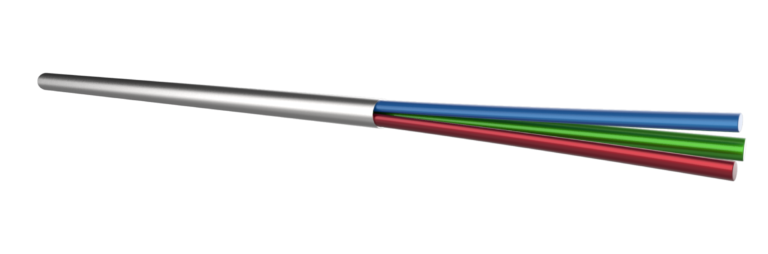

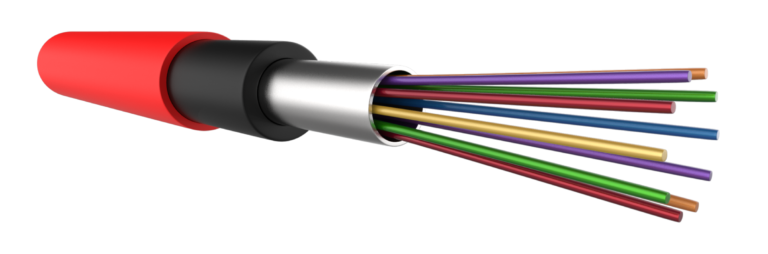

Universal cable

- Polyamide protection

- Rodent resistant

- Accessories (MAAK system)

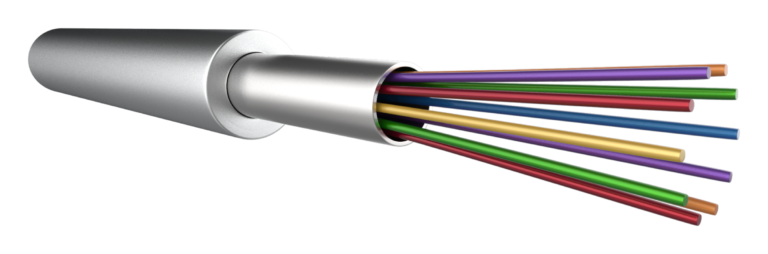

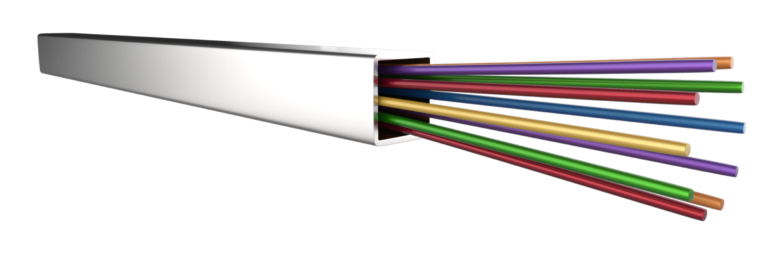

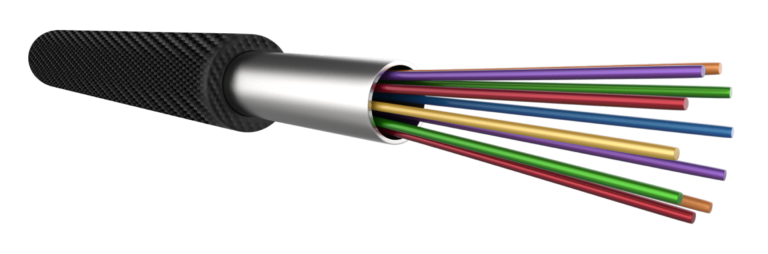

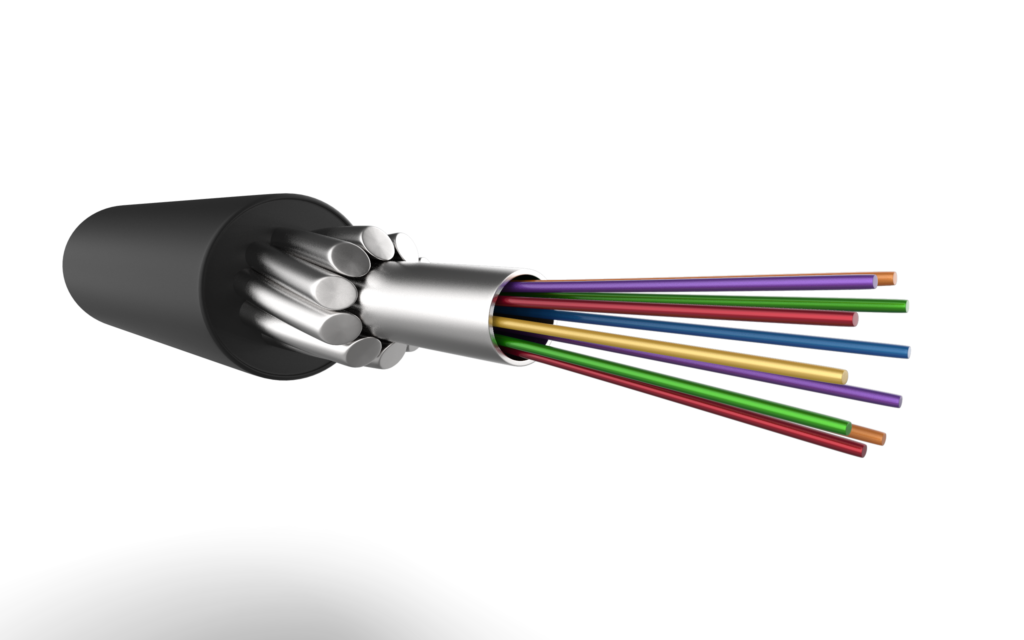

Harsh environmental cable

- ¼” Design

- Extreme performance

- Corrosion resistance

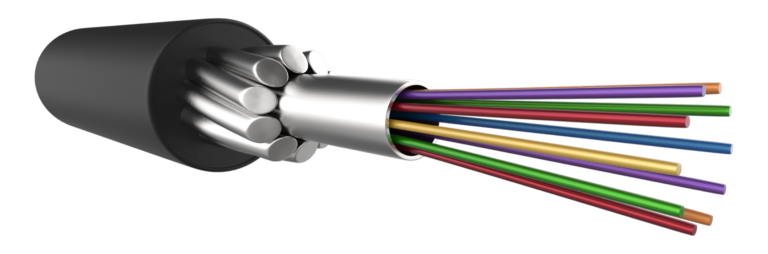

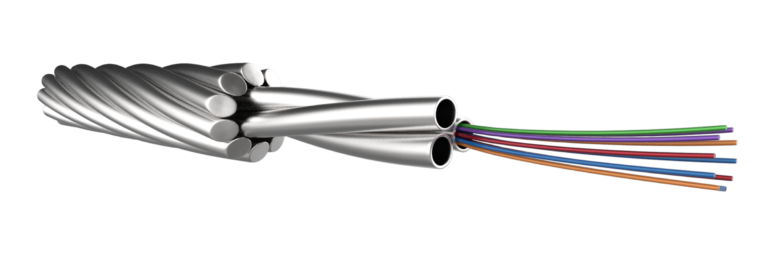

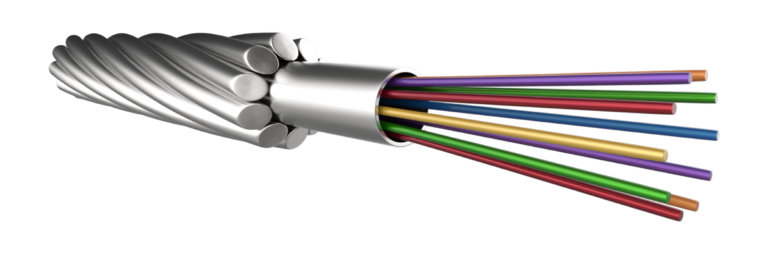

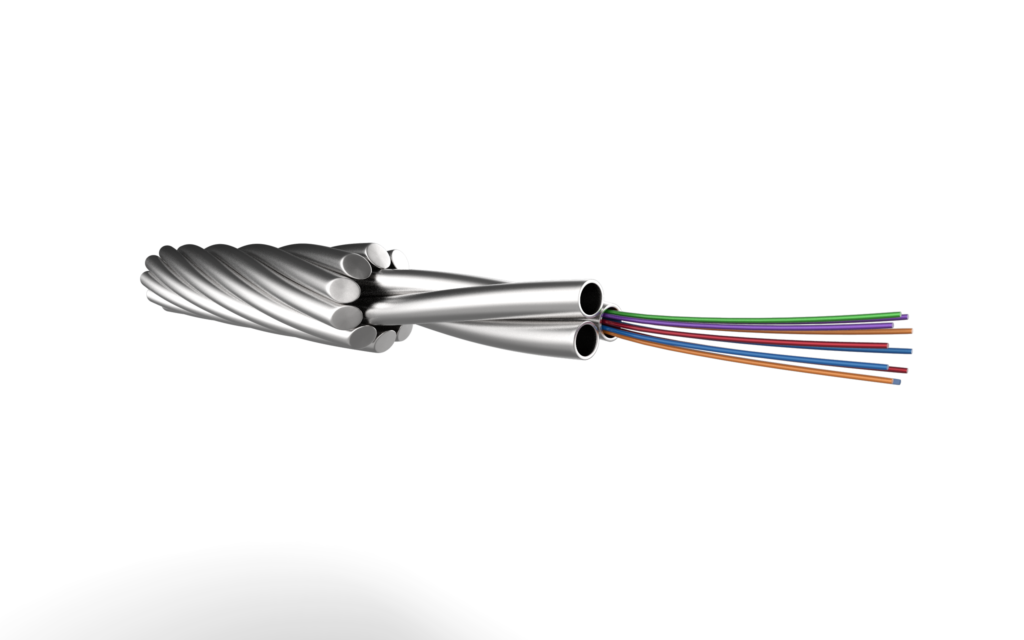

Self-supporting downhole cable

- Tensile strength > 42 kN

- Up to +400°C

- Up to 15 km continuous length